Choosing the right approach for ground preparation is critical in construction projects. Soil composition varies widely across Canada, from loose sandy textures to dense clay layers. Each condition demands specific strategies to ensure stability, safety, and efficiency during site preparation.

Unpredictable terrain can lead to costly delays or safety risks without proper planning. PAR’s Services Ltd specializes in adapting to these challenges, offering customized solutions for projects of all scales. With over two decades of experience, our team ensures your groundwork aligns with regional regulations and environmental factors.

This guide explores how factors like moisture content, compaction levels, and geological features influence operational decisions. We’ll cover equipment selection, safety protocols, and site-specific adjustments that keep projects on schedule. For immediate assistance, call PAR’s Services Ltd at +(604) 278-4445.

Key Takeaways

- Soil characteristics directly impact site preparation strategies and equipment choices

- Proper planning prevents project delays and minimizes safety risks

- Local environmental factors require region-specific adaptation in Canada

- Professional expertise ensures compliance with construction standards

- Custom solutions improve efficiency across diverse terrain conditions

Understanding Soil Types and Their Impact on Excavation

Overview of Sand, Silt, Clay, and Loam

Granular sand particles drain water rapidly but lack cohesion. This creates easy digging conditions that require constant slope monitoring. Silty textures hold moderate moisture, offering better compaction than sand but less stability than clay.

Clay’s dense structure makes it:

- Resistant to water penetration

- Prone to expansion when saturated

- Challenging to shape without specialized tools

Loam combines sand, silt, and clay in balanced proportions. This mixture provides optimal drainage while maintaining structural integrity.

Key Soil Properties and Their Effects on Digging

Moisture content dramatically alters material behavior. Sandy terrain becomes unstable when dry, while wet clay turns adhesive. Recent geotechnical studies show:

- Clay requires 30% more machine power than loam

- Sandy sites need 50% more slope reinforcement

Professional analysis before breaking ground prevents cave-ins and equipment damage. PAR’s Services Ltd uses advanced testing to map subsurface conditions, ensuring strategy matches reality.

Excavation Methods for Different Soil Types

Soil composition directly determines which machinery and techniques deliver optimal results. Loose textures demand different handling than dense layers, requiring operators to adapt their approach. Proper selection prevents delays, equipment strain, and unexpected costs.

Techniques for Sandy and Loamy Soils

Granular materials like sand allow rapid digging with standard backhoes or track loaders. Their natural drainage minimizes water-related issues but requires slope stabilization. Loam’s balanced structure enables efficient grading and compacting without excessive reinforcement.

| Material | Recommended Equipment | Key Benefit | Average Timeline |

|---|---|---|---|

| Sandy | Backhoe | Fast removal | 5-7 days |

| Loamy | Track Loader | Natural compaction | 3-5 days |

Approaches for Working with Clay and Silt

Clay’s density often requires excavators with hydraulic rippers to break hardened layers. Silt’s moisture retention extends drying periods before backfilling. A 2023 geotechnical study revealed projects in clay-rich regions took 40% longer than loam-based sites.

Matching tools to ground conditions reduces wear on machinery components. For instance, using wider buckets in sticky soils prevents material buildup. These adjustments maintain productivity while protecting your investment in heavy equipment.

Assessing Site Conditions and Interpreting Geotechnical Reports

Proper site evaluation forms the backbone of successful construction planning. Before any ground preparation begins, professionals analyze geological data to predict material behavior under stress. This critical step prevents costly revisions and ensures worker safety throughout the project lifecycle.

Importance of Soil Testing and Report Analysis

Geotechnical reports provide a roadmap for navigating subsurface challenges. Teams collect core samples to measure density, moisture levels, and load-bearing capacity. For example, clay with high water content may require dewatering systems before shaping.

Key parameters in these documents include:

| Testing Method | Parameters Measured | Purpose | Frequency |

|---|---|---|---|

| Core Sampling | Layer density | Stability assessment | Every 50m² |

| Moisture Content | Water saturation | Predict expansion risk | Daily |

| Shear Strength | Internal friction | Slope angle limits | Per soil layer |

Identifying Potential Hazards from Soil Variations

Unexpected material changes account for 27% of construction delays nationwide. Loose sand pockets beneath clay layers can collapse without warning. Silty zones near water tables often liquefy under equipment vibrations.

Technical reports highlight risk areas through color-coded maps and stability indexes. Teams use this information to implement specific protective measures like:

- Slope reinforcement grids for granular soils

- Drainage channels for moisture-rich zones

- Compaction protocols for mixed-layer sites

Accurate interpretation of these details allows crews to adjust timelines and machinery choices. This proactive approach reduces equipment wear while maintaining strict safety standards across Canadian job sites.

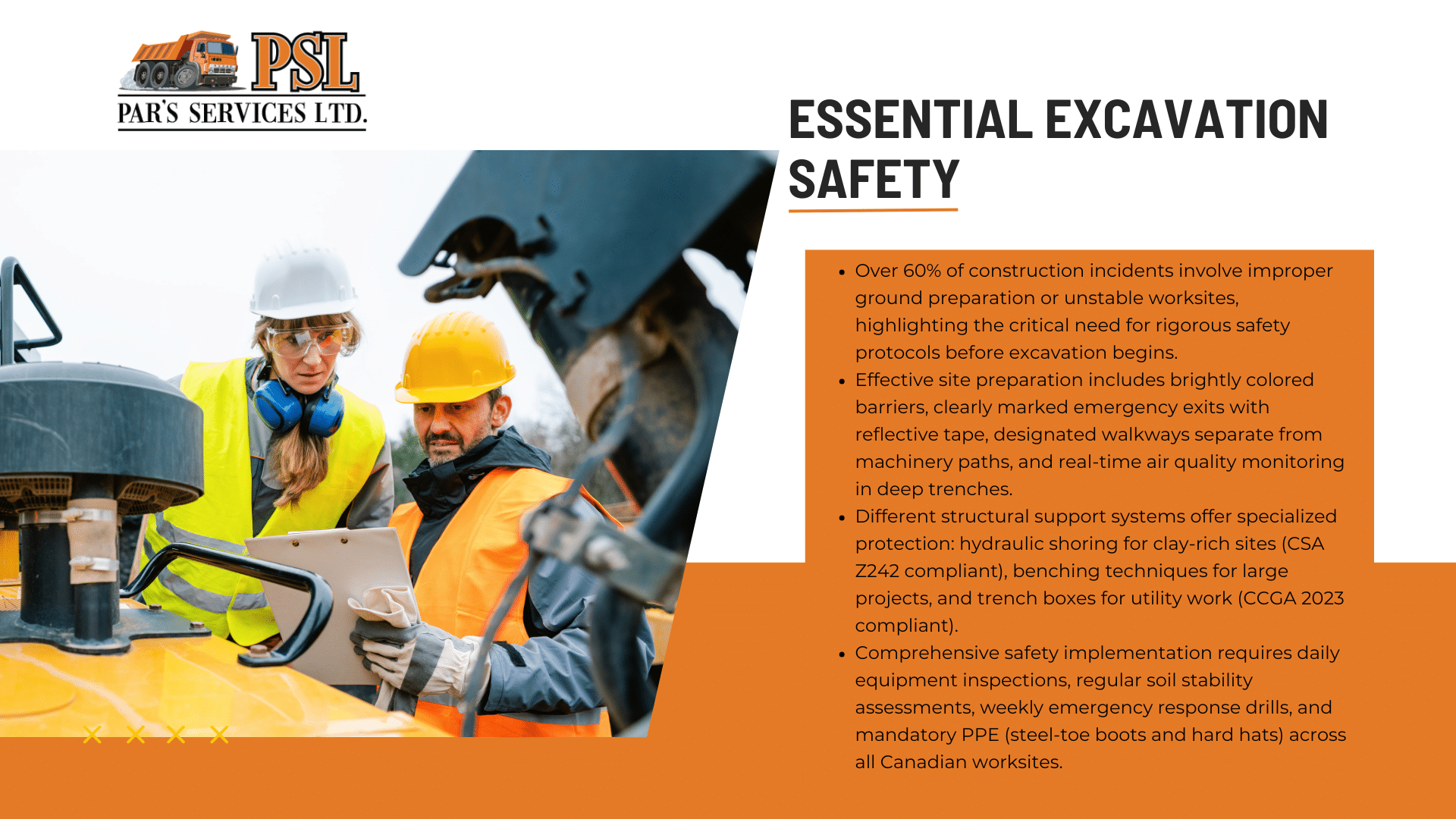

Essential Safety Measures for Excavation Projects

Prioritizing worker protection prevents accidents and keeps projects moving forward. Over 60% of construction incidents involve improper ground preparation or unstable worksites. Rigorous protocols ensure teams address risks before they escalate.

Building a Secure Foundation

Clear communication starts with visible safety markers. Brightly colored barriers and warning signs define hazardous zones. Daily equipment checks and soil stability assessments help crews adapt to changing conditions.

Key elements for site preparation include:

- Designated walkways away from active machinery

- Emergency exit routes marked with reflective tape

- Real-time air quality monitoring in deep trenches

Structural Support Solutions

Shoring systems provide critical reinforcement in unstable areas. Aluminum hydraulic braces prevent wall collapses in narrow trenches. Sloping techniques reduce pressure on excavation walls by cutting them at safe angles.

| System Type | Best For | Key Benefit | Compliance Standard |

|---|---|---|---|

| Hydraulic Shoring | Clay-rich sites | Adjustable support | CSA Z242 |

| Benching | Large-scale projects | Step-style stability | OHSA Section 234 |

| Trench Boxes | Utility installations | Worker shielding | CCGA 2023 |

Weekly safety drills keep response protocols fresh. Certified inspectors review equipment placements and soil conditions every shift. Proper PPE like steel-toe boots and hard hats remains mandatory across all Canadian sites.

Choosing the Right Equipment and Techniques Based on Soil Conditions

Efficient ground operations depend on matching machinery to subsurface challenges. Operators must balance power requirements with material behavior to protect both workers and investments. Modern construction demands precision tools that adapt to regional variations across Canadian landscapes.

Optimal Equipment Selection for Challenging Soils

Track loaders excel in loamy terrain due to their weight distribution and grading precision. For dense clay, hydraulic excavators with ripper attachments break through compacted layers without excessive strain. A 2023 equipment study showed:

- Rippers reduce engine stress by 40% in clay

- Wide-track bulldozers prevent sinking in silty zones

| Soil Type | Recommended Tool | Efficiency Gain |

|---|---|---|

| Clay | Hydraulic Ripper | 55% faster |

| Silt | Low-Ground-Pressure Dozer | 30% less refueling |

| Loam | Laser-Guided Grader | 20% precision boost |

Managing Project Time and Preventing Equipment Wear

Daily maintenance checks extend machinery lifespan in abrasive environments. Scheduling deep digs during dry periods minimizes clay adhesion to buckets. PAR’s Services Ltd uses telematics to monitor engine loads, adjusting work cycles to prevent overheating.

Integrating Safety Protocols and Effective Digging Strategies

Real-time slope monitoring systems alert crews to instability risks during operations. Combining shielded trench boxes with vacuum excavation reduces cave-in hazards by 62%. Teams conduct equipment orientation sessions before handling moisture-sensitive materials.

Proper tool selection cuts project timelines by 25% while maintaining compliance with CSA safety standards. For tailored solutions matching your site’s needs, contact PAR’s Services Ltd at +(604) 278-4445.

Conclusion

Projects thrive when teams prioritize industry standards. Proper shoring systems prevent trench collapses, while slope adjustments maintain structural integrity. Matching machinery to material characteristics – such as using rippers for dense clay – reduces delays by 40% in challenging terrain.

Every site demands tailored strategies. Loam’s balanced texture allows faster grading, while sandy zones require reinforced barriers. Regular inspections and real-time monitoring ensure compliance with Canadian safety regulations throughout the project lifecycle.

PAR’s Services Ltd combines technical expertise with localized knowledge to navigate these complexities. For optimized results in your next project, call +(604) 278-4445. Our team delivers compliant, efficient solutions across all major Canadian soil classifications.