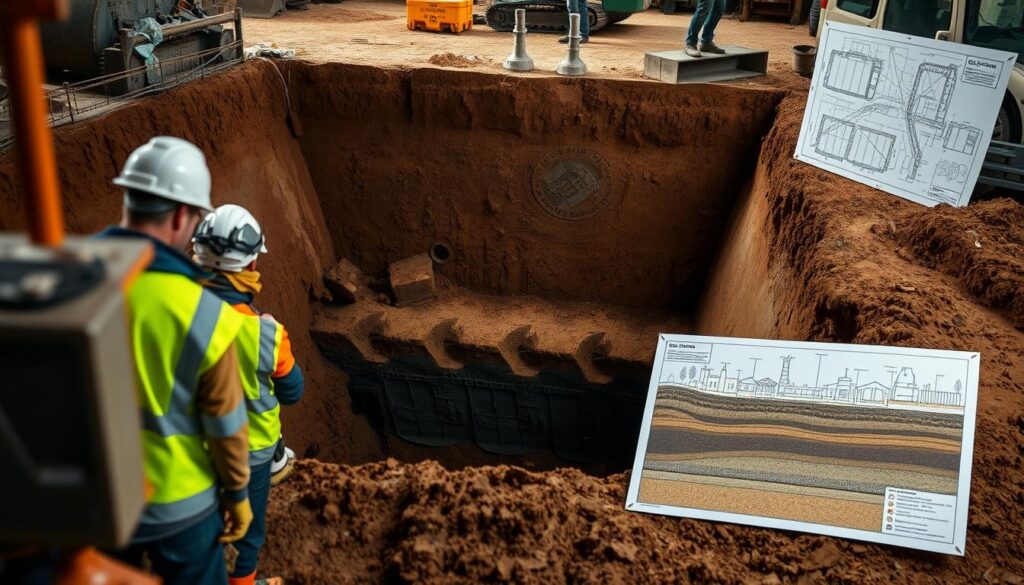

Construction and underground work need strict safety rules. WorkSafeBC sets up detailed excavation safety rules in BC to keep workers safe. These rules are key to a safe work place in many industries.

PAR’s Services Ltd knows how complex safety rules can be. We help companies follow WorkSafeBC’s strict safety standards. Our team makes sure workers are protected during excavation projects.

Following excavation safety rules in BC requires knowing all the details. From telling WorkSafeBC about underground projects to safety gear standards, these rules cover all worker safety and risk management.

Key Takeaways

- WorkSafeBC defines excavation as any cut, cavity, trench, or depression in the earth’s surface

- Underground projects require 30-day advance notification

- Worker safety guidelines mandate strict supervision and safety protocols

- Comprehensive risk assessments are essential for all excavation work

- Proper training and equipment are mandatory for worker safety

Need help with excavation safety compliance? Call PAR’s Services Ltd at +(604) 278-4445.

Understanding WorkSafeBC Regulatory Framework

WorkSafeBC is key in setting up safety rules for construction and excavation in British Columbia. It helps keep workers safe and makes sure places of work are safe.

The group defines construction projects widely. This includes everything from moving earth to fixing buildings. Excavation permit requirements are a big part of these rules.

Scope of Construction Projects

WorkSafeBC’s rules cover many construction tasks. These include:

- Land clearing and earth moving

- Structural and routine maintenance

- Excavating and trenching

- Installation of machinery

- Blasting and drilling operations

Definition of Excavation Work

Excavation work is clearly defined for easy compliance. For example, a trench is considered an excavation if it’s less than 3.7 m (12 ft) wide at the bottom and over 1.2 m (4 ft) deep.

Regulatory Compliance Requirements

To follow WorkSafeBC rules, you need to do several things:

- Submit notices of project for certain types of work

- Keep detailed safety records

- Use the right safety measures

- Make sure you have the right equipment and safety gear

The rules cover 33 different Parts. Each part deals with construction, safety, and protecting workers.

Excavation Safety Regulations BC

Excavation safety in British Columbia is a big deal. It requires following WorkSafeBC standards and doing a thorough soil stability check. Construction workers must stick to strict rules to keep everyone safe and the project on track.

Important steps before digging include:

- Request location information at least three business days before digging

- Contact BC 1 Call to notify member companies with buried utilities

- Obtain utility maps from service providers like FortisBC

The soil stability assessment process is key. It involves several important steps:

- Identify underground utility locations

- Implement hand digging to expose buried utility lines

- Mark gas lines with paint or stakes

- Establish safe excavation zones

WorkSafeBC has strict safety rules for excavation. These include setting clear dig zones and avoiding dangers.

| Regulation Area | Key Requirements |

|---|---|

| Utility Identification | Confirm underground utility locations before excavation |

| Safety Zone | Maintain one-metre buffer around gas lines |

| Notification | Submit notice of project 24-48 hours before work begins |

Contractors must put safety first. They need to know and follow these excavation safety rules in BC. This protects workers and the infrastructure.

Notice of Project Requirements

WorkSafeBC has strict rules for excavation permits to keep workplaces safe. It’s important for construction pros and contractors in British Columbia to know about the Notice of Project (NOP) process.

Starting excavation projects means following detailed rules. The NOP is a key tool to avoid accidents and follow the law.

When NOP is Required

A Notice of Project is needed in certain situations:

- Excavations deeper than 1.2 m (4 ft)

- Construction projects over $100,000 in total cost

- Buildings taller than 2 storeys or 6 m (20 ft) high

- Bridges and water structures over 3 m (10 ft)

Submission Process and Documentation

Site inspection checklists are essential for NOP documents. Contractors need to provide:

- Estimated total project cost

- Project start date

- Expected project length

- Details on site safety measures

Emergency Work Provisions

WorkSafeBC allows for quick action in emergencies. Emergency excavation work can skip some NOP steps, but safety documents are a must.

Good communication and detailed records are vital for safety in excavation projects.

Qualified Contractor Requirements

WorkSafeBC sets high standards for contractors in excavation projects. They make sure only skilled professionals handle complex work. Contractors must show they are ready and safe for the job.

The main things contractors need to be qualified include:

- Mandatory registration with WorkSafeBC

- Good standing with occupational health and safety regulations

- Comprehensive understanding of worker safety guidelines

- Proven experience in excavation projects

Personal protective equipment is key for contractors. They must:

- Know how to pick and use PPE

- Have the right PPE for workers

- Keep PPE in good shape

- Check safety equipment often

WorkSafeBC rules say contractors need a safety program for big projects. The Prime Contractor is in charge of safety for everyone. They make sure all contractors follow safety rules.

Contractors must focus on safety by training, keeping equipment up, and following WorkSafeBC rules.

Site Assessment and Planning

Starting a successful excavation project needs careful site assessment and planning. Knowing about underground utility locating and soil stability is key. It keeps workers safe and makes the project run smoothly.

Underground Utility Identification

Finding underground utilities is the first important step in excavation. WorkSafeBC requires detailed steps to avoid damage and keep everyone safe.

- Use specialized underground utility locating equipment

- Do detailed site surveys before digging

- Mark utility lines accurately

- Keep a detailed map of utilities

Soil Classification Systems

Knowing about soil types is vital for assessing soil stability. These systems help guess how the ground will behave and what risks there might be during digging.

| Soil Type | Stability Characteristics | Excavation Considerations |

|---|---|---|

| Clay Soils | Low permeability | Needs careful shoring |

| Sandy Soils | High drainage | May collapse |

| Loam Soils | Moderate stability | Generally easier to dig |

Site-Specific Safety Plans

Creating detailed safety plans for each site is critical. These plans must tackle the project’s unique challenges and include soil stability checks.

- Do a thorough site check

- Record the ground conditions

- Find where underground utilities are

- Plan how to avoid risks

Good planning stops project delays and keeps workers safe during digging.

Trench Safety Standards

WorkSafeBC sets important rules for trench safety. They define trenches based on size. Knowing how to shore trenches is key to keeping workers safe.

Important safety rules for trenches are:

- Trenches over 1.2 meters (4 feet) deep need protective systems

- Materials dug up must be at least 1 meter from trench edges

- A trained person must check the trench at the start of each shift

When entering trenches, following strict safety rules is vital. Workers need thorough safety training and must assess risks carefully. Important safety steps include:

- Checking for dangerous gases and oxygen levels before going in

- Wearing the right protective gear

- Having a clear plan for getting out quickly in an emergency

Using the right trench shoring techniques is critical to avoid cave-ins. The type of soil affects the needed support. Good engineering and support systems are key to keeping the trench safe.

Safety is not an option—it’s a mandatory requirement in excavation work.

Employers must focus on keeping workers safe. They should provide detailed training, do regular site checks, and follow WorkSafeBC’s trench safety rules closely.

Shoring and Support Systems

Trench shoring techniques are key for keeping workers safe in excavation projects. WorkSafeBC rules require specific safety measures for underground work. Knowing how to use shoring systems can greatly lower the risk of accidents.

Excavation work is full of challenges that need strict safety rules. For trenches over 1.2 meters (4 feet) deep, strong support systems are vital for safety.

Types of Shoring Equipment

- Timber Shoring: Traditional wooden support for smaller digs

- Steel Trench Boxes: Strong protection for deeper work

- Hydraulic Shoring: Adjustable for different soil types

- Aluminum Shoring: Light and easy to move support

Installation Requirements

Putting shoring equipment in place right is key for safety. Important steps include:

- Checking the soil type and stability

- Making sure pressure is evenly spread

- Keeping safety distances

- Checking if the equipment is strong

Maintenance Protocols

Keeping shoring systems in good shape is important for safety. Workers should check them every day for:

- Damage

- Corrosion

- Alignment

- How well they work

Safety is not an accident – it’s a deliberate and continuous process of vigilance and preparation.

Worker Protection Measures

Keeping workers safe during excavation projects is key. WorkSafeBC sets strict rules to protect them in tough underground spots.

Good safety plans have many layers of protection. Employers need to cover all possible dangers in excavation work.

- Mandatory personal protective equipment must include:

- Hard hats with chin straps

- Steel-toed boots

- High-visibility safety vests

- Protective eyewear

- Respiratory protection

Creating safety barriers is part of the plan. Barrier systems and warning signs are critical components of worker safety. They stop accidents and warn of dangers.

- Key safety monitoring protocols include:

- Regular site risk assessments

- Continuous communication systems

- Designated safety observers

- Emergency response planning

Training is vital for using PPE right. Workers need to know why each piece is important for their safety.

Safety is not an option—it’s a requirement for every excavation project.

Safe Access and Egress Requirements

Excavation sites need strict safety rules to keep workers safe when entering and leaving. WorkSafeBC sets clear guidelines for safe movement in and around these areas. This includes rules for confined space entry and emergency plans.

Getting in and out safely is key for worker safety. Excavations over 1.2 meters deep need special entry and exit points. These must meet strict rules.

Entry and Exit Points

Effective site access involves many important factors:

- Fixed ladders are needed for level changes over 450 mm

- Passageways must have at least 2.2 m vertical clearance

- Guardrails are required for openings with drops over 1.2 m

- Walkways should support a minimum live load of 6 kPa

Emergency Evacuation Procedures

Emergency response plans are vital for quick and safe evacuations. Key needs include:

- Clear escape routes

- Emergency exits that are easy to find

- Regular training on confined space entry

- Quick communication systems

Employers must take a detailed approach to safety. This includes careful planning for access, egress, and emergency evacuations. The focus is always on protecting workers.

Excavation Depth Considerations

Excavation depth is key to workplace safety, mainly in construction and industrial settings. WorkSafeBC sets strict safety rules for digs over 1.2 meters (4 feet) deep. Knowing these rules is vital to avoid accidents.

Assessing soil stability is critical at different depths. Each depth level poses unique risks and needs specific safety measures. Using trench shoring techniques is vital to keep workers safe and prevent ground collapses.

- Excavations deeper than 4 feet need detailed safety steps

- Soil stability checks must be ongoing

- Protective systems should match the site’s conditions

Important safety points for excavation depths include:

- Checking soil type and moisture levels

- Using the right shoring or sloping methods

- Having the right protective gear

- Doing regular risk assessments for the site

A single cubic yard of soil can weigh as much as a car. This shows how important managing excavation depth is. Employers must focus on worker safety. They should follow detailed soil stability checks and use advanced trench shoring methods.

Safety is not an option—it’s a requirement in every excavation project.

Soil Stability and Ground Conditions

Excavation work needs careful attention to soil stability and ground conditions. WorkSafeBC stresses the importance of detailed soil stability checks to avoid hazards during construction.

Ground conditions greatly affect excavation safety. Different soils pose unique challenges for construction teams.

Assessment Methods for Soil Stability

Effective soil stability checks involve several steps:

- Visual ground inspection

- Geotechnical soil testing

- Comprehensive geological surveys

- Moisture content analysis

Site Inspection Checklists for Ground Monitoring

Using detailed site inspection checklists is key for excavation safety. These checklists help track important ground condition details.

| Soil Characteristic | Stability Risk Level | Recommended Action |

|---|---|---|

| High Moisture Content | High Risk | Immediate stabilization required |

| Vibration Sensitivity | Moderate Risk | Reduce nearby mechanical activity |

| Previous Excavation Areas | Elevated Risk | Additional structural reinforcement |

Weather affects soil stability a lot. Rain, snowmelt, and temperature changes can quickly change ground conditions. This means constant monitoring and adjusting safety measures is needed.

WorkSafeBC suggests checking ground conditions often, mainly for long excavation projects. Proactive soil stability checks can stop big failures.

Conclusion

Understanding excavation safety rules in British Columbia is key. PAR’s Services Ltd knows how important it is to keep workers safe. They work hard to follow all safety rules in complex environments.

Employers need to focus on training and safety checks. WorkSafeBC has rules like setting up safety teams and following safety guidelines. These rules help prevent accidents and keep workers safe during tough projects.

Following safety rules means being prepared in many ways. This includes keeping records, doing safety checks, and having plans for emergencies. PAR’s Services Ltd helps companies follow these rules closely.

If you need help with safety rules in BC, call PAR’s Services Ltd at +(604) 278-4445. Our team is ready to help make your workplace safer. We’ll guide you through the safety rules with care and knowledge.