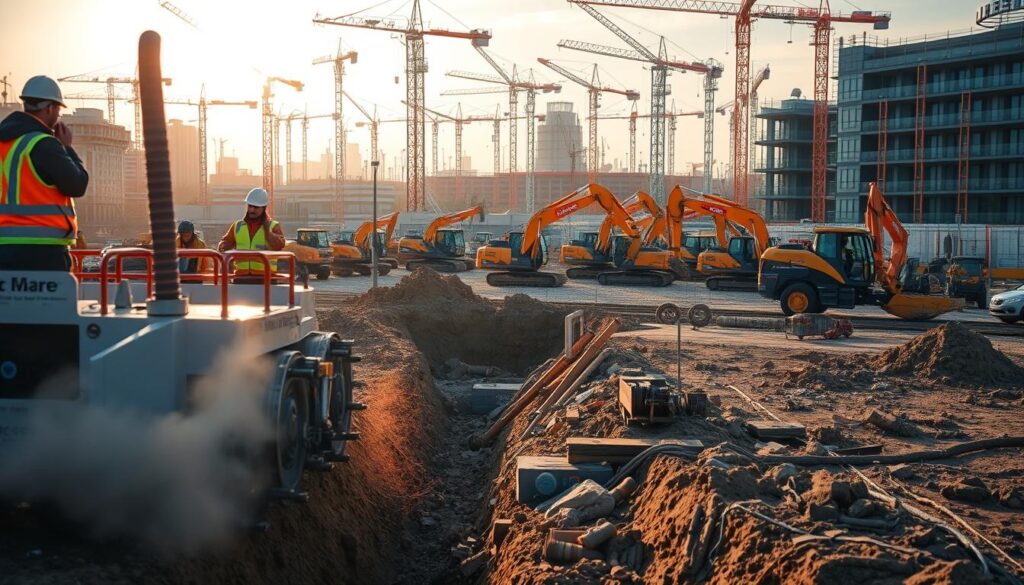

Excavation equipment is key in modern construction. It helps contractors handle tough terrain with ease. PAR’s Services Ltd (+(604) 278-4445) knows how important these machines are.

The world of excavators and equipment keeps getting better. Contractors now have advanced tools for digging and moving materials. There are machines for every need, from big excavators to small track loaders.

Choosing the right equipment is vital for contractors. It affects how fast a project goes, its cost, and how well the site works. Knowing what each machine can do helps pick the best one for the job.

Key Takeaways

- Excavation equipment is essential for efficient construction

- Machine selection depends on specific project needs

- Modern excavators have advanced technology

- Choosing the right equipment boosts project productivity

- Safety and training are key in using equipment

Understanding Modern Excavation Equipment

The construction world has changed a lot thanks to new machines. Excavation tools are key to modern building, making projects more precise and efficient.

The journey of construction machines is really interesting. It shows how technology has improved from simple diggers to complex hydraulic systems. This change has greatly impacted how we do construction work.

Technological Advancement in Construction Machinery

Tools like backhoes and trenchers have changed construction a lot. Some big changes include:

- Precision hydraulic control systems

- Advanced GPS tracking

- Enhanced safety features

- Improved fuel efficiency

Role in Contemporary Construction

Backhoes and trenchers are very important in building projects. They can dig up to 14 feet deep, and some can even go 25 feet deep. They are very flexible, helping contractors with many different tasks.

Impact on Project Efficiency

These machines make projects faster and cheaper. Hydraulic excavators are very precise, which means less mistakes and more work done. The right machine can make hard construction jobs easier.

Modern excavation technology represents the intersection of engineering prowess and practical innovation.

Choosing the right equipment is very important. It depends on the project, the land, and how much money you have. Good machines mean better projects and more work done.

Excavation Equipment Guide: Key Considerations

Choosing the right excavation equipment is key to a project’s success. Contractors need to weigh many factors for the best performance and efficiency. They must match the project’s needs with the right machinery.

When picking out equipment like skid steer loaders and bulldozers, contractors should look at a few important things:

- Project scale and specific requirements

- Site conditions and terrain complexity

- Equipment size and power capabilities

- Fuel efficiency and operational costs

- Long-term maintenance needs

Different machines have their own strengths. Skid steer loaders are great for small spaces, while bulldozers are top for moving earth. Choosing the right machine for the job is key to being productive and saving money.

Big names like Caterpillar, John Deere, and Komatsu have a wide range of equipment. Their machines weigh from 13 to 124 metric tons. This gives contractors lots of options for different projects.

| Equipment Type | Weight Range | Primary Applications |

|---|---|---|

| Mini Excavators | 8-13 metric tons | Tight urban sites, residential projects |

| Standard Excavators | 13-45 metric tons | Commercial construction |

| Large Excavators | 45-124 metric tons | Heavy-duty demolition, mining |

Spending time on choosing the right equipment is worth it. By carefully picking their machines, contractors can cut costs and improve project efficiency.

Heavy-Duty Excavators and Their Applications

Excavators are key in construction and earthmoving. They help dig deep, clear debris, and shape landscapes. Contractors use different types for various projects, from small urban sites to big industrial areas.

Today’s excavators are made for many terrains and challenges. Each model has special features for better compaction and grading.

Crawler Excavators: Stability Masters

Crawler excavators are great for tough terrains. They have a tracked undercarriage for stability. They are known for:

- Superior traction on uneven ground

- Weight distribution for enhanced balance

- Ability to navigate rough construction sites

Wheeled Excavators: Urban Performance Champions

Wheeled excavators are perfect for urban areas and paved surfaces. They are great for:

- Quick site transitions

- Road construction projects

- Municipal infrastructure work

Mini Excavators: Compact Powerhouses

Mini excavators are great for small spaces. They are small but powerful, with:

- Precision in tight work areas

- Reduced ground disturbance

- Enhanced maneuverability

“Selecting the right excavator is key for project success and saving money.” – Construction Equipment Experts

| Excavator Type | Weight Range | Primary Applications |

|---|---|---|

| Crawler | 20-50 tons | Heavy earthmoving, rough terrain |

| Wheeled | 15-40 tons | Urban projects, road construction |

| Mini | 1-10 tons | Landscaping, residential work |

Knowing about these excavators helps contractors choose the best for their projects. This improves grading and overall project success.

Backhoe Loaders in Construction Projects

Backhoe loaders are key in modern construction. They are versatile and used in many projects. These machines have the power of a loader and an excavator, making them essential for contractors.

Backhoe loaders are small but can move well in tight spaces. They have four-wheel drive for better performance on different terrains. This makes them great for road work and utility projects.

“Backhoe loaders are the Swiss Army knife of construction equipment, capable of transforming job sites with remarkable efficiency.”

Key Capabilities and Demolition Equipment Functionality

- Excavate trenches up to 14 feet deep

- Handle multiple demolition equipment attachments

- Operate in confined urban and rural landscapes

- Perform precise material handling tasks

Versatile Attachments for Enhanced Performance

Modern backhoe loaders have many attachments. Contractors can change them quickly. This includes:

- Hydraulic hammers

- Pallet forks

- Auger systems

- Specialized buckets

| Attachment Type | Primary Function | Best Use Case |

|---|---|---|

| Hydraulic Hammer | Breaking concrete | Demolition projects |

| Rake Riddle Bucket | Sorting materials | Site clearance |

| Auger | Drilling holes | Utility installations |

Choosing the right backhoe loader is important. You need to think about the project’s needs. This includes the engine power, hydraulic strength, and attachments needed. Keeping the machine well-maintained ensures it works well on all construction tasks.

Bulldozers: Earth Moving Powerhouses

Bulldozers are key in changing construction sites with great power and accuracy. They have changed how contractors handle tough terrain in many fields.

The history of bulldozers goes back almost a century. They started with steam power in the 1920s and now use diesel. They have gotten better at doing their job over time.

Track Bulldozers: Stability Masters

Track bulldozers are great for tough places because they are very stable. They are perfect for:

- Navigating soft or uneven terrain

- Mining operations

- Large-scale construction projects

- Heavy earth-moving tasks

Wheel Bulldozers: Mobility Specialists

Wheel bulldozers are better at moving around than track bulldozers. They are great for:

- Highway construction

- Urban site preparation

- Faster transportation between work sites

- Smooth surface operations

Advanced Operating Techniques

Today’s bulldozers use cool tech like GPS guidance and remote operation systems. This lets operators work more precisely, saving time and effort.

Keeping workers safe is very important. Good training and following rules help bulldozers work well and keep everyone safe.

Trenching Equipment Essentials

Trenching is key in construction and utility work. Contractors use special trenchers and backhoes for precise digs. Knowing the right tools boosts project speed and safety.

There are many trenching tools for different jobs. Walk-behind trenchers and ride-on models are great for many tasks. They’re used for everything from irrigation to laying down utility lines.

- Walk-behind trenchers have 12-15 hp engines

- 4WD trenchers with 120 hp are for big projects

- Directional drills range from 25 hp to 600 hp

Keeping safe is top priority with trenching gear. OSHA rules require safety gear for deep trenches. Before starting, think about the soil, trench depth, and dangers.

| Trencher Type | Engine Power | Typical Application | Approximate Cost |

|---|---|---|---|

| Walk-behind | 12-15 hp | Sprinkler Systems | Under $20,000 |

| Ride-on | 60-70 hp | Medium Construction | Under $80,000 |

| Quad Track | 120+ hp | Large Infrastructure | $225,000-$250,000 |

Today’s backhoes and trenchers have cool features. They help with accuracy and speed. Contractors should think about their project, the soil, and their budget when picking the best equipment.

Skid Steer Loaders and Versatility

Skid steer loaders have changed the game in construction and excavation. Their small size and great versatility make them stand out. These machines have grown from simple tools to complex devices that can do many jobs.

Today’s skid steer loaders are super easy to move around. They can fit into tight spots. Their design lets operators quickly switch tasks with special attachments, making them key for contractors.

Attachment Options for Maximum Flexibility

Skid steer loaders are amazing because of their many attachments. They can turn into different machines for various jobs. Some common attachments include:

- Buckets for moving materials

- Augers for drilling

- Trenchers for digging

- Hydraulic hammers for breaking things

- Brush cutters for landscaping

Maintenance Requirements

Keeping skid steer loaders in top shape is important. Here are some key maintenance steps:

- Check the hydraulic system often

- Do a quick check of the equipment every day

- Oil the moving parts regularly

- Replace worn-out parts on time

Safety Protocols

It’s vital to follow strict safety rules when using skid steer loaders. Operators need good training, the right gear, and should follow the maker’s instructions.

| Model | Horsepower | Operating Capacity |

|---|---|---|

| Caterpillar 262D3 | 74 hp | 2,200 lbs |

| John Deere 332G | 100 hp | 3,600 lbs |

| Bobcat S86 | 105 hp | 2,500 lbs |

Now, skid steer loaders come with the latest tech like backup cameras and interactive screens. This makes them safer and more efficient.

Motor Graders for Precision Grading

Motor graders are key in construction and road projects. They make uneven land smooth and level. They are a big part of any excavation equipment guide, showing how technology helps prepare sites.

Motor graders have changed a lot, thanks to new tech. GPS and hydraulic systems help operators grade perfectly. This cuts down on mistakes and makes projects better.

- Precision surface leveling for road construction

- Creating stable foundations for infrastructure projects

- Preparing agricultural and mining sites

- Snow removal and winter road maintenance

New tech has made motor graders very advanced. SmartGrade™ Technology gives operators more control. They can:

- Lean front wheels with precision

- Control articulation accurately

- Pitch blade movements automatically

| Feature | Benefit |

|---|---|

| GPS/GNSS Installation | Error-free automated operations |

| Hydraulic Systems | Enhanced blade control and accuracy |

| Rollover Protection System | Operator safety in challenging environments |

Big names like Caterpillar, John Deere, and Komatsu keep improving motor graders. They meet many project needs. These machines are the best for precise grading in road, farm, or mining work.

Compaction Equipment Selection

Choosing the right compaction equipment is key for a stable structure and project success. Construction experts need to look at soil types, project needs, and machine abilities. This careful selection is vital.

Modern compaction tools are essential for site preparation. They increase soil density and its ability to hold weight. Each type of compactor is designed for different project settings.

Soil Compactors: Understanding Key Characteristics

Soil compactors have various designs to tackle different terrains. Contractors have many options:

- Smooth drum compactors for granular soils

- Padfoot compactors for cohesive materials

- Combination rollers for versatile use

Vibratory Plates for Precision Compaction

Vibratory plates are great for small areas. They are perfect for tight spaces and efficient soil stabilization. Important factors include:

- Vibration frequency

- Surface area coverage

- Soil particle characteristics

Roller Compactors for Large-Scale Projects

Roller compactors are vital for big projects. Bulldozers help prepare and level the ground with these tools.

| Compactor Type | Ideal Soil Type | Recommended Application |

|---|---|---|

| Smooth Drum | Sand, Gravel | Road Base Layers |

| Padfoot | Clay, Silt | Foundation Preparation |

| Tandem Roller | Asphalt | Road Construction |

Intelligent compaction technology is changing the game. It makes soil stabilization more precise and efficient in various construction settings.

Material Handling Solutions

Material handling is key in construction and industry. Excavators with special attachments move heavy stuff efficiently. The market for this equipment is expected to hit $250 billion by 2026, showing big growth.

Good material handling boosts productivity. It can cut downtime and boost work by up to 25%. Contractors need the right gear and attachments to keep things running smoothly.

- Grapple attachments for excavators enable quick handling of irregular materials

- Specialized buckets improve material collection and transportation

- Fork attachments enhance versatility in material placement

Safety is a big deal in material handling. OSHA says proper training can cut injuries by 40%. Using the right attachments can also cut manual labor by up to 50%, making them a smart choice for teams.

| Material Handling Equipment | Load Capacity | Efficiency Improvement |

|---|---|---|

| Excavator Grapples | 2-10 tons | 30-40% |

| Specialized Buckets | 1-5 tons | 25-35% |

| Fork Attachments | 3-7 tons | 35-45% |

Modern excavators with advanced attachments are changing material handling. They use automated systems and new designs to work better. This lets contractors handle tough tasks with great precision.

Demolition Equipment Specifications

Demolition equipment is key in today’s construction and renovation. It helps contractors tear down buildings safely and efficiently. The field has grown, using new tech to boost safety and work speed.

Contractors use top-notch equipment for tough demolition jobs. Excavators are vital, working well in many demolition tasks.

Hydraulic Breakers: Precision Demolition Tools

Hydraulic breakers are vital for breaking concrete and hard materials. They’re strong attachments for excavators, working well on big and small projects.

- Average excavator size range: 0.7 to 140 tons

- Critical for foundation demolition

- Capable of precise concrete and stone removal

Crushing Attachments: Material Management Solutions

Crushing attachments make demolition better by recycling materials and managing waste. Multi grapples are key for sorting materials after demolition.

| Attachment Type | Primary Function | Material Compatibility |

|---|---|---|

| Concrete Pulverizer | Separate steel from concrete | Reinforced concrete structures |

| Multi Grapple | Material sorting | Mixed construction debris |

Safety Measures in Demolition Operations

Safety is top priority in demolition. Contractors follow strict rules to keep workers and areas safe. Controlled demolition techniques and new excavation tools lower risks in demolition.

- Conduct thorough structural assessments

- Implement dust control mechanisms

- Use remote-controlled demolition equipment when possible

- Ensure proper operator training

Today’s demolition gear keeps getting better, focusing on being green and using the latest tech. This makes work more efficient and kinder to the environment.

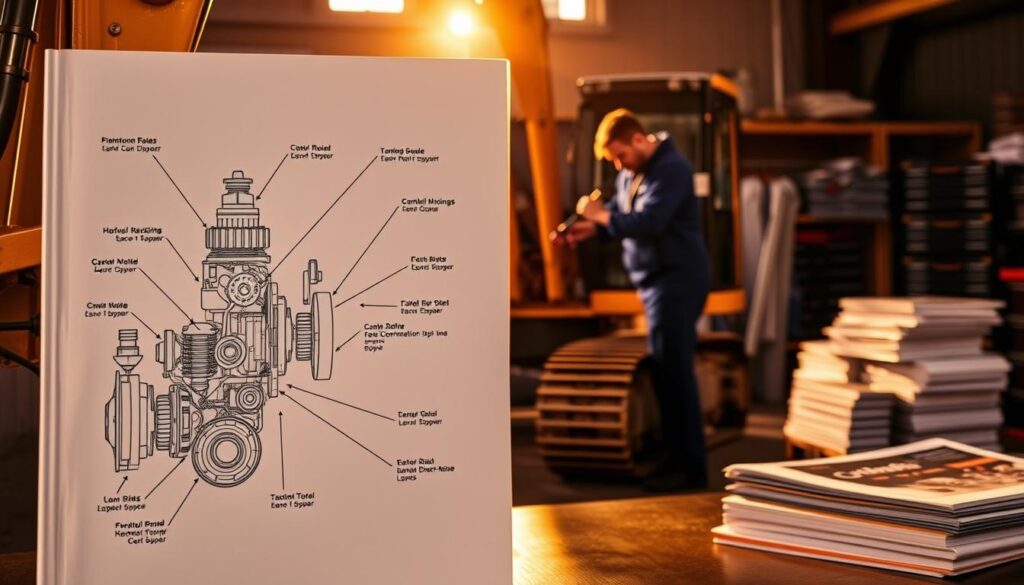

Equipment Maintenance Best Practices

Keeping excavation equipment in top shape is vital for contractors. A good maintenance plan can cut down on unexpected breakdowns by 30%. This means less project delays and better work flow.

For those using backhoes and other heavy machinery, a detailed maintenance plan is essential. Regular checks and early fixes can make your equipment last longer. It also helps save money in the long run.

- Do daily pre-operation inspections to spot problems early

- Keep an eye on fluid levels and how much you use the equipment

- Stick to a maintenance schedule

- Teach operators how to handle the equipment right

Telematics systems have changed the game for equipment upkeep. These advanced tools let you:

- Watch how your equipment is doing in real-time

- Plan maintenance ahead of time

- Check how much fuel you’re using

- Find mechanical problems before they get worse

Contractors can get help from pros like PAR’s Services Ltd (+(604) 278-4445). Their skilled team can create maintenance plans that fit your specific needs.

Proactive maintenance isn’t just a cost—it’s an investment in your equipment’s reliability and project success.

By focusing on maintenance, construction pros can cut emergency repair costs by 50%. They can also boost work efficiency by 20%. Regular upkeep means safer, better-performing equipment and more value over time.

Safety Protocols and Operator Training

Construction safety is key to successful excavation projects. It’s important to protect workers when using trenchers and skid steer loaders. This requires thorough training and following safety rules closely.

Effective safety management in excavation work involves several strategies. These help reduce risks and keep workers safe.

Certification Requirements

Getting certified is a must for safe construction work. Here are the main certification needs:

- Finish OSHA-approved training programs

- Show you know how to use trenchers and skid steer loaders

- Get recertified every year

- Pass both practical and theory tests

Emergency Procedures

Quick action in emergencies can stop big accidents. Important emergency steps include:

- Shut down equipment right away

- Have clear ways to talk to each other

- Know the best ways to leave the site

- Be ready for first aid and medical help

Site Safety Guidelines

Good site safety needs careful planning and sticking to safety rules.

| Safety Aspect | Required Action |

|---|---|

| Personal Protective Equipment | Wear hard hats, safety glasses, steel-toed boots, and high-visibility vests |

| Equipment Inspection | Check equipment every day before use, keep maintenance records |

| Communication | Use hand signals, radios, and have spotters |

“Safety is not an accident. It is a deliberate strategy of prevention and protection.” – Construction Safety Expert

Keep training, watch for risks, and always focus on safety. This helps lower dangers in excavation work.

Equipment Rental vs. Purchase Considerations

Choosing between renting and buying excavation equipment needs careful thought. Contractors must look at many factors that affect their budgets. Fuel costs often make up a big part of expenses, whether you rent or own.

Bulldozers and other heavy machines come with their own set of challenges. For short-term projects, renting is often the best choice. It saves money upfront and lets you use the latest equipment without a long-term commitment.

For longer projects, owning equipment might be better. Buying can lead to lower payments over time, thanks to good interest rates. Owning bulldozers also means you can customize them and use them for more projects. Plus, you might get tax benefits when you sell them.

The construction world is starting to see the benefits of renting. It lets businesses avoid the hassle of storing and fixing equipment. This way, they can focus on their main work and always have access to top-notch equipment. Whether to rent or buy depends on how long the project is, your budget, and what you need to do.